Keep Cool

Ultra-High Resolution Cameras with Thermoelectric Cooling

Two new ultra-high-resolution models with 151MP and 101MP are added to Vieworks product line-up. Both models include Thermoelectric Cooling (TEC) using Peltier effect.

Image 1 | Pictures taken with the VC-151MP camera with the thermoelectric cooling (TEC) turned off (l.) and on (r.) with one second. (Image: Vieworks Co., Ltd.)

The resolution of the VP-151M camera is 151MP and the VP-101M is 101MP. Both are based on the Sony CMOS image sensors IMX411 and IMX461 respectively. The VP-151M is available in monochrome and colour versions. This model has a slightly lower resolution and much slower frame rate than the VC-155 camera, based on Vieworks’ proprietary 155MP sensor. However the dynamic range of the VP-151M is much higher with 78dB. The camera is perfect for customers who are interested in ultra-high resolution, but do not require highest image acquisition speed. The image sensor has a resolution of 14,192×10,640 pixels and a pixel pitch of 3.76µm. The size is large enough to have high sensitivity and to avoid the limitations of a camera system modulation transfer function (MTF). Even though the sensor size is 66.7mm diagonally, it is still smaller than Medium Format cameras and there are many M72 format lenses of manufacturers like Schneider, Zeiss, Qioptic or Opto Engineering which can be used with the camera.

Compact TEC modules

The interesting fact is that Vieworks introduced initially only a cooled model of the camera. The VP-151M camera uses Vieworks own TEC module. Thanks to this signature design, the temperature of the sensor can stay at constant temperature of 15 degrees below the ambient temperature. In addition, the module is capable of removing unwanted moisture which could cause condensation on the Peltier heat sink. Over the years, the company has perfected the design of TEC modules making them small enough to assure compact camera design. The camera will come only in CoaXPress interface allowing acquisition with up to 6.2fps at full resolution. As with all other camera models, the VC-151M will have all the basic camera features implemented, such as: different pixel depths (8/10/12bit), independent horizontal and vertical binning, analogue and digital gain, Lookup Table (LUT) etc. In addition, all of Viework’s image processing functions and correction techniques, have also been added. Some of the correction functions are for Flat Field, defective pixel (both dynamic and static), cluster defect, DSNU, PRNU hot pixel correction and others. Based on EMVA1288 standard measurements the dynamic range of the VP-151M is 78dB, the Dark Noise at maximum gain less than 7e-, DSNU less than 1.17e-, PNRU below 0.3 percent and linearity >1 percent. Mechanically the VC-151M is with 110x110x83mm compact despite including the TEC module.

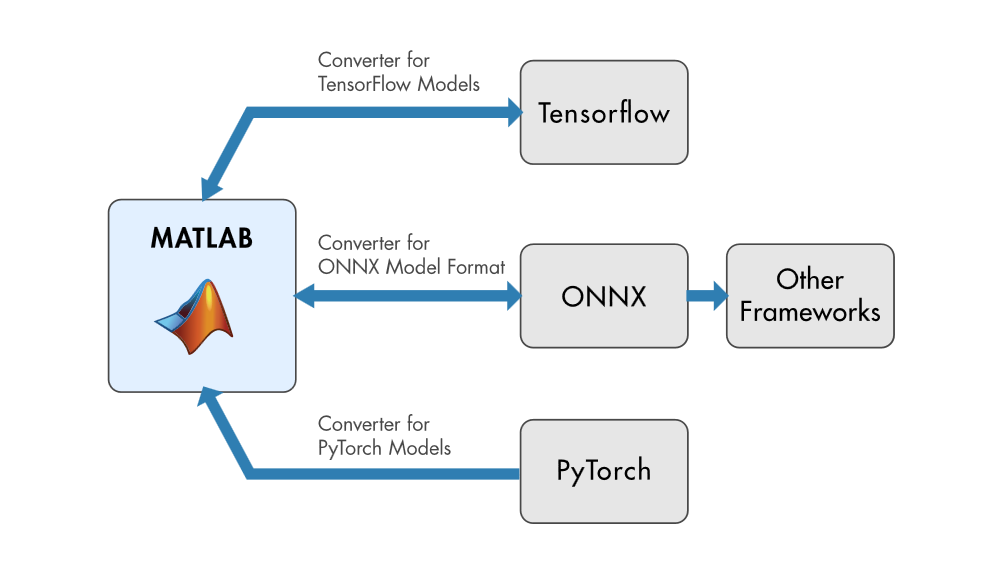

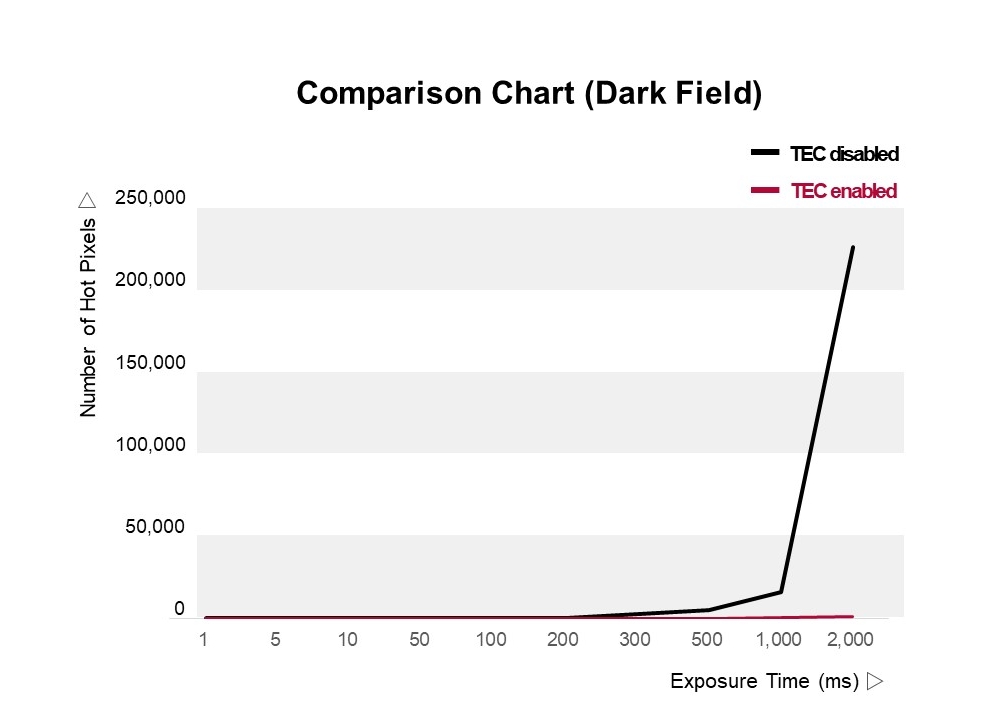

Image 2 | Comparison chart of ‘hot pixels’ between TEC enabled and disabled. (Image: Vieworks Co., Ltd.)

Avoiding hot pixels

The camera has been designed for applications requiring very high resolution without the need of high-speed acquisition. Many of such users require very long exposure times and need to maintain the highest image quality. A perfect example is Flat Panel Display inspection, where long exposure times are used to capture screen under test with different levels of dark test patterns. With exposure times of up to one second and beyond, the amount of noise and number of defective pixels (hot pixels) grow exponentially. Hot pixels are a type of read noise where current leakage increases with temperature. Vieworks cooled cameras assure that this doesn’t happen and the captured images are good enough for evaluation of the actual defects on an object under inspection. Figure 1 shows examples of pictures taken with the VC-151MP camera with the TEC turned off (l.) and on (r.) with one second exposure time. The sensor inside the camera without cooling can get as hot as 48°C and at such a high temperature the dark current is extremely high. As a result, the incidence of hot pixels is therefore very high and the image looks like starry sky from Cerro Tololo Observatory in Chilean Andes – designated the first International Dark Sky Sanctuary. Images with so much noise and hot pixels are practically useless in flat panel inspection systems. If we now compare it with the picture, where the sensor has ambient temperature minus 15°C (r.), the image has only a limited number of hot pixels easily addressed by Vieworks’ effective pixel correction techniques. Figure 3 shows the actual numbers of hot pixels, where there could be almost a quarter of a million of them. Still not as many as the stars, but enough to make the image unworkable. The camera has already been adopted by several users in Flat Panel Inspection, PCB Inspection, BGA Inspection and inspection of unidentified large objects (ULO; named as such because of confidentiality agreements). The camera is capable to inspect OLEDs because of low noise in dark areas.

Conclusion

In instances where recording speed is not the most important consideration, mainly due to long acquisition times, the outstanding image quality of the VP151-M resulting from cooling of the sensor, give the users an ability to capture ultra-high resolution images with unparalleled quality.