Virtual GigE

GigE Vision Server and Camera Simulator

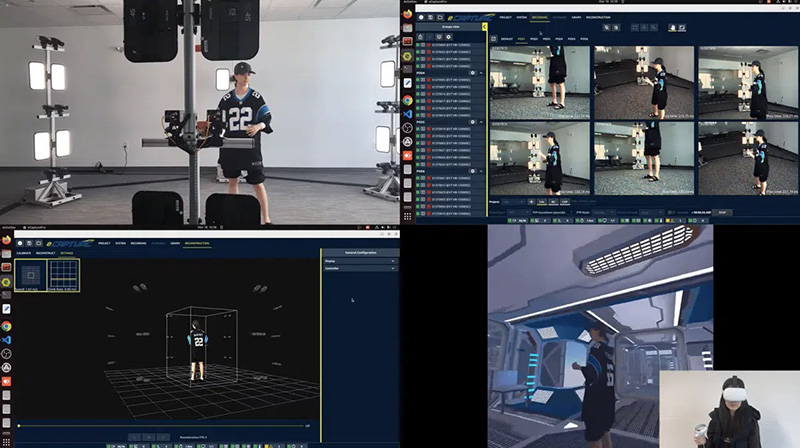

GigESim is a software package that allows end-users and developers to turn their computer or embedded system into a set of virtual GigE Vision and GenICam compliant cameras.

Image 1 | GigESim camera simulator and ActiveGigE viewer transmitting/receiving a simulated 3D point cloud pattern per GigE Vision 2.1 standard. (Image: A&B Software, DTS)

In a typical image processing system, a GigE Vision device serves as an image transmitter while a software application is used as a client that receives images and sends control commands to the transmitter. However, due to the duplex nature of the Ethernet interface, this classic relationship between vision hardware and software can be modified by utilizing a GigE Vision software simulator such as GigESim. A host PC or embedded board running a GigESim-based application appears on the network as a certified GigE Vision and GenICam compliant device.

Camera Simulator

Application developers and testers can substitute GigE Vision cameras with one or several instances of an emulator application included with the GigESim package. In addition to providing a convenient camera replacement in situations when physical cameras are not readily available, the emulator serves as a ´golden´ GigE Vision device supporting advanced aspects of the standard, such as multiple streaming channels, IEEE-1588 synchronization, 10GigE networking, line-scan and 3D image types, H.264 real-time encoding, message event, and chunk data. The emulator can also simulate rigorous network conditions by disordering and skipping video packets, thus allowing manufactures and integrators to validate the robustness and performance of their GigE Vision receivers.