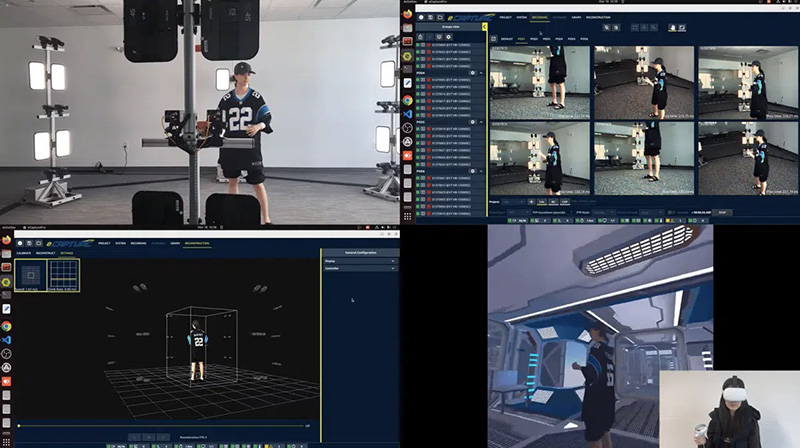

Following the joint release of five telecentric lenses, the two Swiss and Japanese companies kicked off a collaboration on an entocentric lens. Why start with the focal length of 12mm? Although this might sound challenging, this is exactly what the fast-growing logistics market needs: parcels of different sizes need to be handled automatically. Vision systems are key to automate sorting, palletizing and bin picking tasks. But the depth of field (DOF) of fixed focus optics is usually not sufficient to cover the required working distance ranges. Attempts in squeezing the optics to high f-numbers and overs-spending on lighting typically result in poor performance. The current existing alternatives, which mostly consist of either bulky and often unreliable mechanical focusing systems or expensive and complex multiple camera systems, are not versatile enough to adapt to industrial demands. With about 250 million parcels shipped each day globally, improved reliability, through-put and read-rates are key to achieving the ambitious targets of short-term delivery. These necessities call for a fast, flexible and yet reliable solution for focusing. While this 12mm lens has been optimized for bar-code reading, it can also benefit quality control applications that require high accuracy. For example, robot-based inspection systems can become a lot more flexible and efficient. An image taken at a far distance (e.g. 1m) can provide an overview while an image at a short WD (e.g. 200mm) will provide higher magnification. The 5x zoom in this case allows the inspection of vastly differing fields of view with the same vision system, resulting in maximal flexibility.

High Resolution & Large FoV

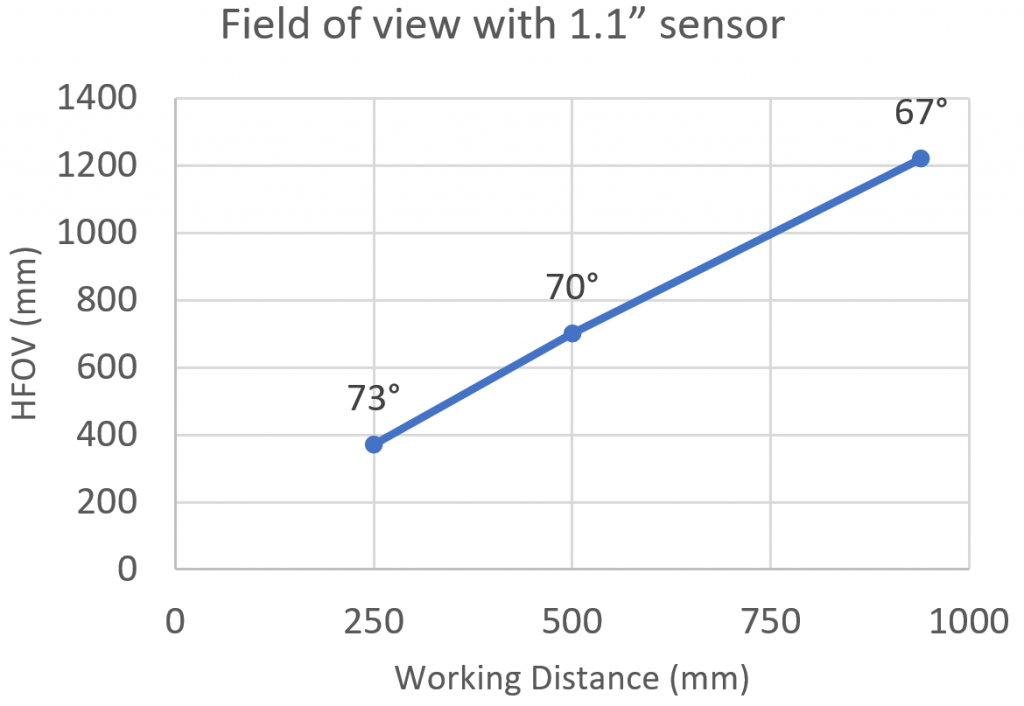

The new 12 mm lens allows to overcome the intrinsic limitations in the DOF and working distance (WD) of standard fixed focal length lenses. Integrated in its core is Optotune’s liquid lens EL-16-40. Controlled by current, the lens can change is curvature to adjust the focus. Such focus changes happen within 20ms, which is orders of magnitude faster than mechanical systems. The liquid lens principle also guarantees reliable and durable adjustment of the WD avoiding the typical mechanical wear and tear, which allows for billions of cycles. This enables fast and reliable execution of autofocus and image stacking routines. In addition, with automatic thermal compensation, the repeatability of the focus is well within the DOF allowing for open loop operation after one-time calibration. The new liquid lens is the first design with integrated liquid lens technology for sensors up to 1.1” format achieving a large field of view (HFOV is 73°). The liquid lens focusing approach even allows for a beneficial zoom effect: for example, when focusing from 250mm to 1000mm WD, the HFOV decreases from 73° to 67°, resulting in a gain of resolution at the longest WD, where the magnification is usually the lowest. The optical performance is optimized for a 1m working distance, i.e. the typical distance to a small parcel on a conveyor belt (where highest resolution is required) and achieves great results across the field for pixel sizes as low as 2.4um. The performance is also maintained when the optical axis is horizontal, as the optimized design minimizes the impact of gravity-induced coma of the liquid lens.

Interface to Cameras

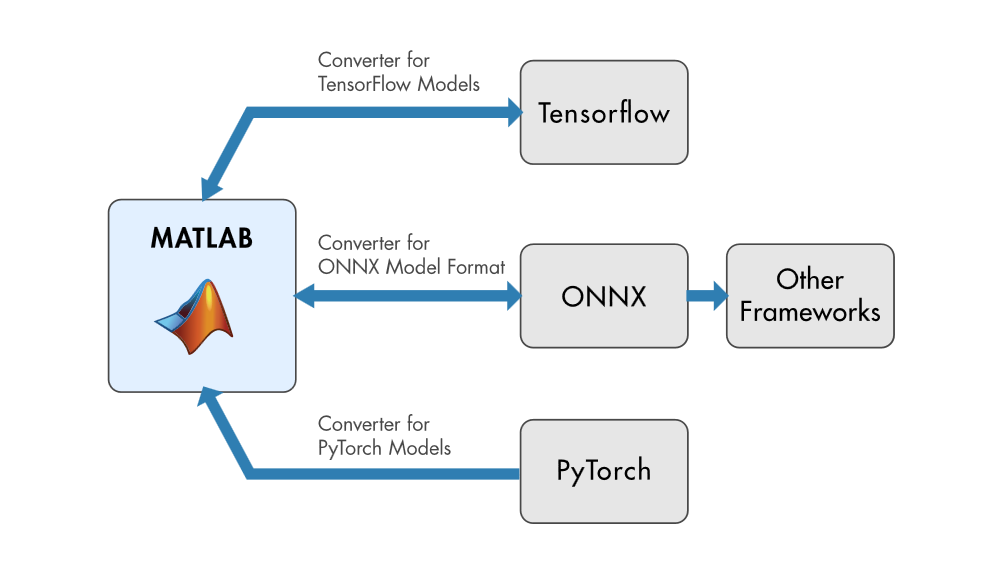

In order to control the liquid lens there are a variety of options, ranging from Optotune’s USB-based drivers to industrial and embedded controllers from Gardasoft, which are GigE Vision compliant. Furthermore, a version of the product with integrated controller allows to interface the liquid lens directly to the camera through UART or I2C. The OOCI workgroup of the EMVA is driving forward the standardization of liquid lenses in the GenICam framework, which will facilitate system integration. To conclude, this new lens will not only be a game changer for logistics applications but also will provide a flexible, compact & reliable solution for all vision systems that require both a large field of view and variable working distance.